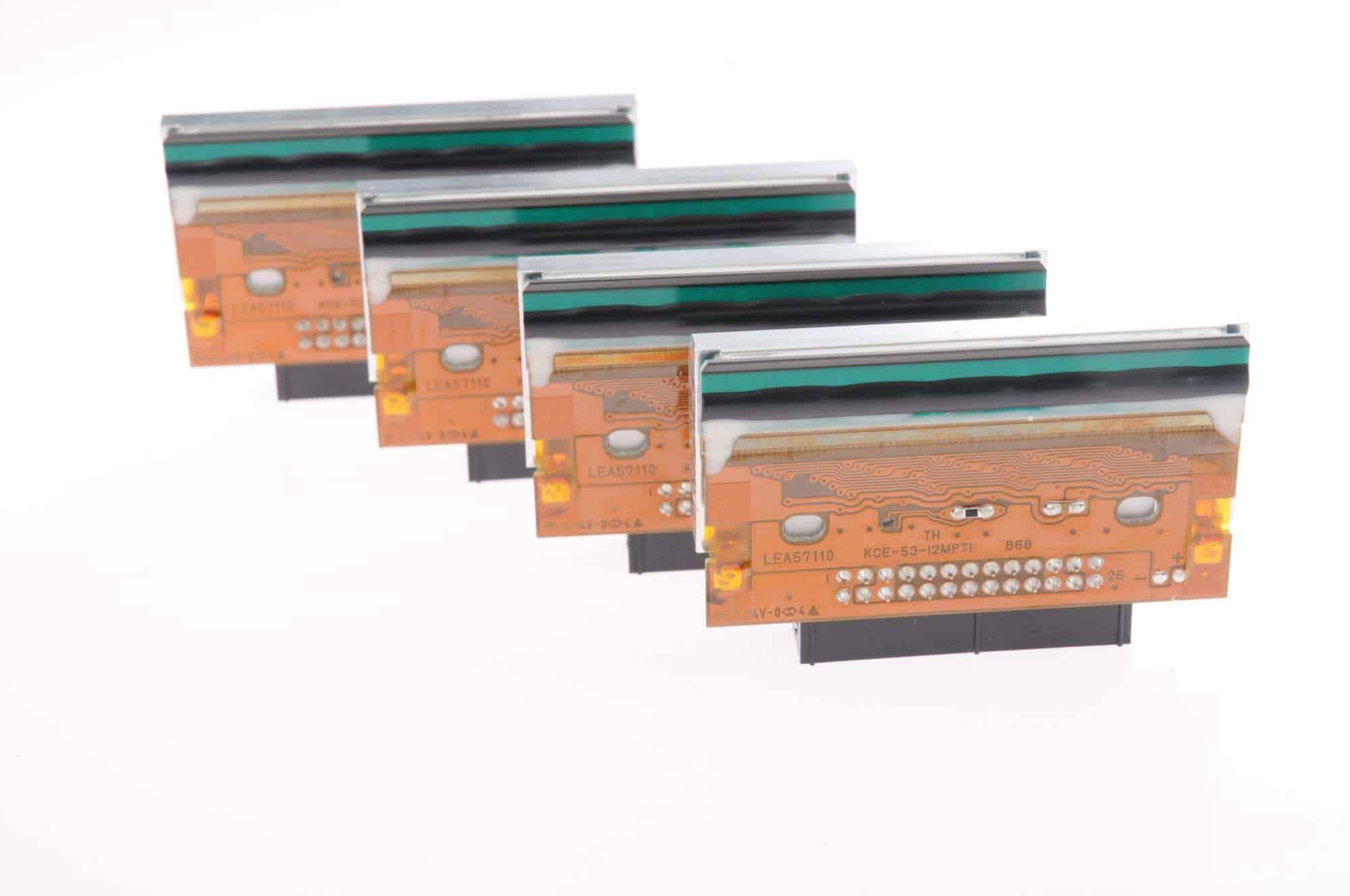

The printhead is the most critical component of any thermal transfer printer and one of the most delicate. It needs to be looked after properly and cleaned regularly in order to enjoy a long life. Unfortunately, we come across a lot of neglected printheads and most print quality problems are actually a direct result of improper care of the printhead.

The big downfall is that printheads can also be very expensive – an additional cost that you do not want to keep incurring because a printhead has just not been cleaned often enough!

Being a consumable that wears over time (much like the brakes on your car), a printhead requires proper installation and on-going maintenance to ensure a long life of service for your printer.

So how often should you be cleaning your printhead?

Well in an ideal world, the printhead would be cleaned every time the thermal transfer ribbon is changed. However, as companies get busier, it is essential that downtime be kept to a minimum and so cleaning a printhead this often would be out of the question.

We recommend that a printhead is cleaned at least once a day. However, the more you clean it – the better! And you will get a much longer life out of it for doing so.

Why do you need to clean the printhead in the first place?

Cleaning the printhead prevents build- up of residue caused by label dust, adhesive and dirt in the atmosphere. This build up of residue will, over time, become baked onto the printhead. This will then interfere with heat transfer, causing the heater elements to overheat to the point of failure.

What can I use to clean my printhead?

There are lots of different products on the market today for printhead cleaning. However, we always recommend using Versawipes (https://www.versawipes.com/) as they have many more advantages in comparison to using other products such as IPA pens.

The biggest advantage being that Versawipes are not limited to just cleaning the printhead. Versawipes can be used to clean the platen roller, label sensors, the printer itself and surrounding areas. So at the end of a shift, you can grab a Versawipe and have an all-round wipe-down – result!